QUALITY

Tryson Metal Stampings & Manufacturing is committed to providing our customers with the highest quality, and we have invested significantly in managing quality across our facilities. We operate a full inspection lab certified to the latest ISO 9001:2015, including a CMM quality inspection process, inspection laser, and optical comparator along with point of operation and process control, and our quality technicians and measuring equipment are SPC capable. If you need any results from our quality inspections of your products, a statistical software package enables us to supply certifications and graphs in any required format.

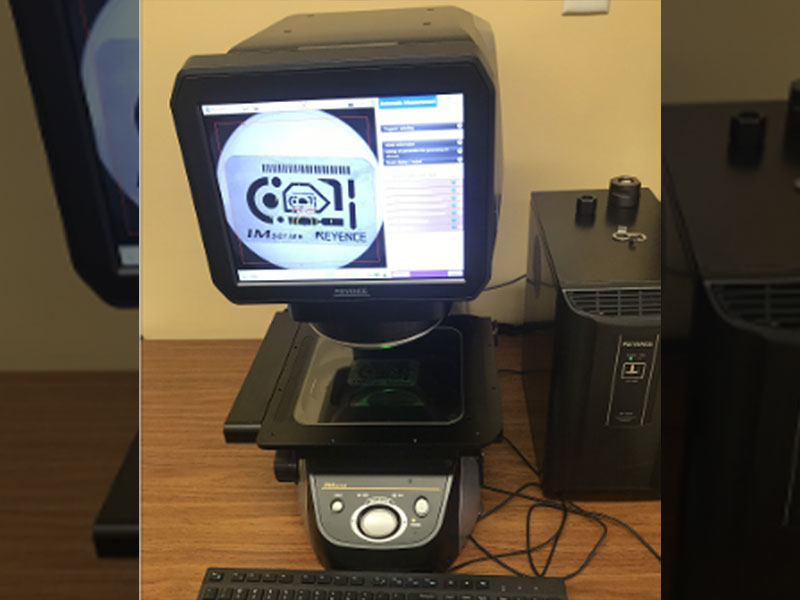

Inspection Equipment

We keep our quality technicians equipped with the latest technology to continuously improve our manufacturing processes, maintain our commitment to ISO9001:2015 standards, and uphold stringent quality control measures throughout our shop.

- Coordinate Measuring Machine

- Laser Dimension Sensor

- Optical Comparator

- Computer – SPC Capable

- Automated valve stem retainer vision inspection machine

- Automated valve stem retainer mechanical/electronic inspection machine (2)

- Digital Indicators

- Digital Calipers

- Calipers

- Micrometers

Certifications

Tryson Metal Stampings & Manufacturing, Inc. maintains a quality management system that is certified to ISO 9001:2015 standards. You can view a downloadable PDF of our certification below.

See what’s new in the industry and at Tryson Metal Stampings!

Ready to partner with a CMM quality inspection expert?

Since 1972, Tryson Metal Stampings & Manufacturing has been a trusted partner for high-speed, high-precision metal stamping services for a wide variety of applications. Whether you’re ready to request a quote or have any questions, don’t hesitate to contact us today to get started! We’d be delighted to learn more about how we can help you.